The Rapid Bander system allows greater

pre-stretch than any other system, ensuring maximum containment with minimum film usage.

Less film usage means less waste material and significant savings in cost per pallet wrapped.

Cost savings is only the beginning.

Our exclusive, patented Rapid Film saves you time and a whole lot more.

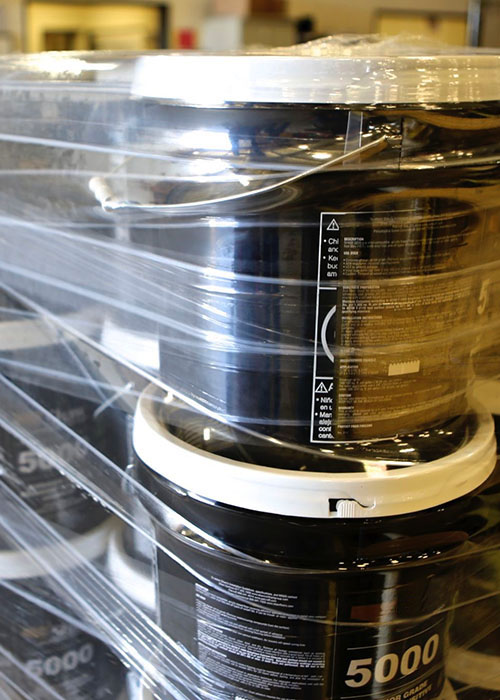

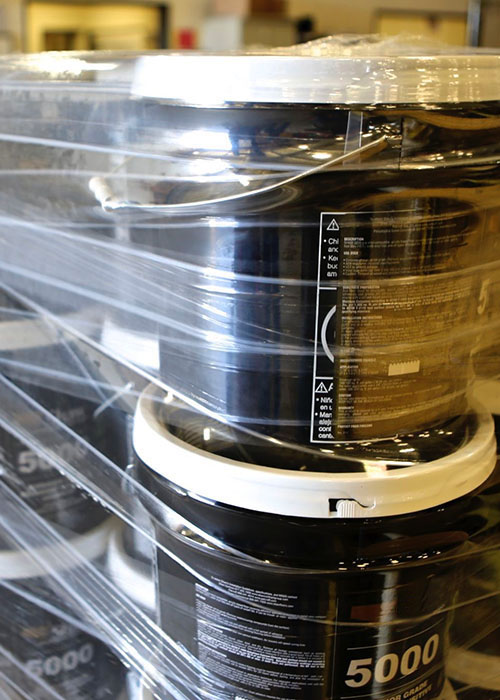

Applying stretch wrap protects the outside of your load, but containment force keeps the load together. With Rapid Bander’s unparalleled pre-stretch capability, we can achieve the ideal containment standard to make sure your product reaches its destination.

The Rapid Film patented reinforced banding system achieves superior containment using up to 60% less film. Less film usage means less waste material and significant savings in cost per pallet wrapped.

Cost savings is only the beginning – our exclusive, patented Rapid Film also saves you time, wear and tear on your equipment, and waste going into the landfill.

Here are some typical savings:

| Example | Current Film | Rapid Film | Your Savings |

|---|---|---|---|

| Number of Loads Wrapped with 2 Pallets of Stretch Wrap |

7123 Pallets | 12,120 Pallets | 70% more pallets wrapped |

| Number of Pallets Wrapped Between Roll Changeover Interruptions |

89 Pallets | 202 Pallets | 127% more pallets wrapped between roll changes |

| Typical Amount of Film Used Per Pallet | 10.2 ounces | 4.4 ounces | 56% reduction of material to landfill |

| Machine Revolutions per Year | 10,080,000 | 5,376,000 | 46% less wear and tear on your equipment |

| Typical Wrap Time per Pallet | 45 seconds | 24 seconds | 46% faster wrap time per pallet |

As if saving time, money, and product integrity at delivery weren’t enough, here’s a summary of some of the many benefits you can expect.

Allied has established a laboratory dedicated to the evaluation and optimization of load containment as a service to our customers.

Each piece of test equipment provides specific data which quantifies the forces exerted on a pallet during shipment. From this data, recommendations are made in a formal report and analysis which is presented to the customer. Objectives can include improved load containment, reduced costs, and increased sustainability.

Our technical staff uses its knowledge of material science and physics to develop a test plan, specific to the customer, analyze the data, and then to make recommendations to help our customers achieve their load containment objectives.

What followed were years of working with customers and suppliers to develop the most innovative and substantial changes in stretch film design and stretch wrap application since these products first began.

Not only did the system we developed yield greater load containment using far less film than other palletizing systems, we discovered that by creating a reinforced web system, we could offer far superior containment on any type of palletized load, wrapping pallets in less time and with far less material.

15 years and 6 patents later, we are revolutionizing the way pallets are wrapped.

Contact us now to find out about our Never Ending Trial with no capital investment from you.

Trained and Ready Our Technicians are carefully selected and thoroughly trained to service the Rapid Bander device and all of our packaging equipment such as stretch wrap machines, conveyors and tape heads.

Free Service and Repairs All Rapid Bander devices are maintained and serviced at absolutely no cost to you. Service and repairs on your existing equipment can be performed at reasonable prices and plans to suit your needs.

Preventive Maintenance Ready and able to service all of your equipment on your maintenance schedule.

202 S. 27th Street Phoenix, Arizona 85034

Phone: 602-305-0100

Email: info@rapidbander.com

If you are a new visitor, contact info@rapidbander.com to request a username and password.

Click the link below to access the distributor portal.